Project

BHP’s PAIP project is a program of works to increase the availability of its Port Hedland iron ore circuits, combining a number of innovative design solutions to reduce operational downtime and planned shutdown durations.

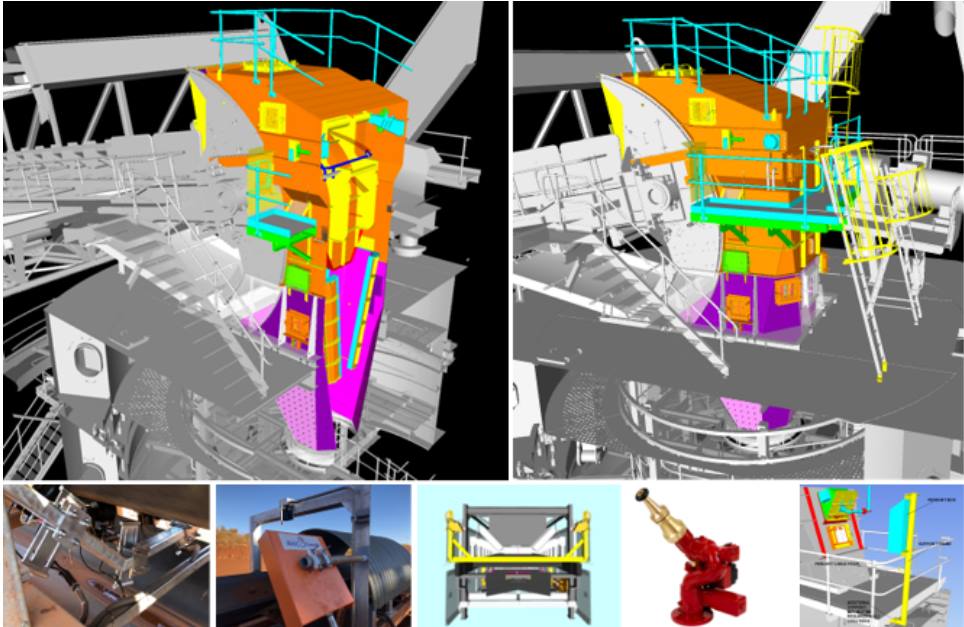

This challenging brownfield project takes advantage of our specialist Root Cause Analysis and Discrete Element Modelling (DEM) capability to improve transfer chute wear life and minimise belt tracking problems. It also includes BHP’s exciting initiative to install automated wash cannons within transfer chutes to eliminate ore build up. Once operational, this solution is likely to be applied across other BHP iron ore facilities.

Having completed the study phases for the project in 2019, Onyx progressively completed the detailed design packages throughout 2020 to meet planned construction windows at the port.

Scope of Work

- Automated transfer chute wash cannons

- Specialised ultrasonic belt rip detectors

- Automated conveyor tracking frames

- Transfer chute maintenance isolation gates

- Transfer chute improvements

Challenges

Successfully co-ordinate the contributions of client, vendor and engineering stakeholders to develop designs for equipment never before used in iron ore site applications.

To apply root cause analysis techniques and DEM expertise to resolve longstanding transfer chute issues; then arrive at inventive design solutions that can be practically installed to minimise disruption to operational plant.

Value Delivered

Collaborated with BHP’s project team and site representatives to implement a constructive design process through successive study and detailed design phases.

Applied complex Root Cause Analysis and advanced DEM modelling techniques to identify and resolve a longstanding Reclaimer transfer chute issue. Regarded by BHP as a project “Brightspot”.

Rigorously applied the design and Safety in Design review process. Especially important due to the introduction of untried technologies within the iron ore handling sector. Specifically modified the design of the transfer chute deflector plate adjustment mechanism to eliminate known safety issues.